SELF-TAPPING SCREWS

TECHNICS

WHICH SCREW FOR WHICH SHEET?

PLATE ON PLATE – THE SAME MATERIAL

Predrilled or punched metal sheets => SELF TAPPING SCREWS

|  |  |  |  |  |

| Inside |  |  |  |  |  |

| |||||

| Outside |  |  |  |  |  |

You will find the alternative for metal sheets without perforation => SELF DRILLING SCREWS

|  |  |  |  |  |

| Inside |  |  |  |  |  |

| |||||

| Outside |  |  |  |  |  |

in our catalogue “SELF DRILLING SCREWS“.

DUPLEX AISI 318LN & AISI 316L

MODERN SOLUTION FOR TODAYS INDUSTRY

Best in class corrosion resistance, reliable long-term performance, waterproof consistency and installation is quick into stainless steel metal jacketing applications.

In conjunction with insulation and construction, the implementation of a suitable metal jacketing system is very important as it provides the foundation for longevity, low maintenance costs, and reduced insulation heat losses. In addition, the importance in using the correct quality of fasteners such as banding, screws, and/or blind rivets plays a decisive role.

Self-Tapping Screws made from AISI 318LN DUPLEX material are 3x harder than AISI 304 or 316 due to the austenite and ferrite structure that ensures a reliable threaded connection without the risk of stripping the threads.

THE BENEFITS:

Safety and reliability remain paramount in our industry on a day to day basis. Our products are used in a large amount of critical applications that demand longevity, durability, and consistent quality. All these characteristics paired with our easy to identify unique designs, specifically the G5 mark and the blue HNBR sealing washer, make our fastener solutions a versatile option for a variety of applications.

SIGNIFICANT ADVANTAGES

DUPLEX 318LN SELF TAPPING SCREWS

+ Made from DUPLEX AISI 318LN (1.4462) Stainless Steel

+ PRE 36 (Pitting Resistance Equivalent) beyond PRE 33 Seawater Resistant

+ 3x harder versus AISI 304 or 316 which in turn prevents snapping or stripping of the threads

+ Delta Seal Coating (Silver) reduces friction while increasing the corrosion resistance of the screw

+ Additional functionality of the Delta Seal Coating is that it acts as a barrier between materials

+ The A Type Thread reduces the installation time by 50% versus ordinary self-tapping screws

+ GOEBEL Quality is easy to identify by our unique G5 Mark & Blue HNBR Washer designs

+ DUPLEX AISI 318LN (1.4462) Stainless Steel Bonded HNBR Sealing Washer

+ HNBR Washer - Higher Weathering Resistance

- Oxidation

- Ozone

- UV Radiation

- Mineral Oils

- Seawater

- Acidic Gases

SCREW DIAMETER / PREDRILLING TABLE / SERVICEABLE THREAD LENGTH

| A | 0,4 mm | 0,5 mm | 0,6 mm | 0,7 mm | 0,8 mm | 0,9 mm | 1,0 mm |

| B | 0,4 mm | 0,5 mm | 0,6 mm | 0,7 mm | 0,8 mm | 0,9 mm | 1,0 mm | |

| S | 0,8 mm | 1,0 mm | 1,2 mm | 1,4 mm | 1,6 mm | 1,8 mm | 2,0 mm | |

| Ø | 4,2 | 4,2 | 4,2 | 4,2 | 4,2/4,8 | 4,8 | 4,8 | |

| S = A + B S ≤ 1,6 mm = Ø 4,2 S = A + B | ||||||||

PLATE ON PLATE – THE SAME MATERIAL

Determination of the recommended screw diameter (ø) in accordance with the thickness of the metal sheet (S)

Predrilling table

| Type of plate | Steel zinc plated | Aluminium | Platal® ZA | Stainless steel A2 | Stainless steel A4 | |

| Ø | ||||||

| Ø 4,2 | S = 0,63-0,88 mm | 3,2 mm | 3,0 mm | 3,2 mm | 3,3 mm | 3,3 mm |

| S = 0,88-1,13 mm | 3,2 mm | 3,0 mm | 3,2 mm | 3,3 mm | 3,3 mm | |

| S = 1,13-1,38 mm | 3,2 mm | 3,0 mm | 3,2 mm | 3,3 mm | 3,3 mm | |

| S = 1,38-2,50 mm | 3,2 mm | 3,0 mm | 3,2 mm | 3,3 mm | 3,3 mm | |

| Ø 4,8 | S = 0,75-1,13 mm | 3,7 mm | 3,7 mm | 3,7 mm | 3,7 mm | 3,7 mm |

| S = 1,13-1,38 mm | 4,0 mm | 3,7 mm | 4,0 mm | 4,0 mm | 4,0 mm | |

| S = 1,38-1,75 mm | 4,0 mm | 3,7 mm | 4,0 mm | 4,0 mm | 4,0 mm | |

| S = 1,75-2,50 mm | 4,0 mm | 3,8 mm | 4,0 mm | 4,0 mm | 4,0 mm | |

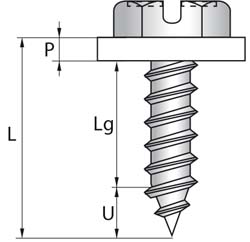

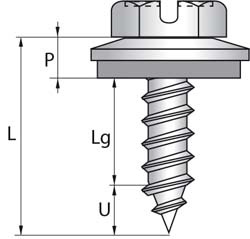

Serviceable thread length (Lg)

|

P = 2,0mm |

P = 3,0mm | ||||

| Lg |

x = max. 1.4mm Ø 4,2 |

x = max. 1.6mm Ø 4,8 | Ø 4,2 | Ø 4,8 | Ø 4,2 | Ø 4,8 |

| 9,5 mm | Lg(min) = 6,7 mm | Lg(min) = 6,3 mm | Lg(min) = 5,7 mm | Lg(min) = 5,3 mm | Lg(min) = 5,2 mm | Lg(min) = 4,8 mm |

| 13 mm | Lg(min) = 10,2 mm | Lg(min) = 9,8 mm | Lg(min) = 9,2 mm | Lg(min) = 8,8 mm | Lg(min) = 8,7 mm | Lg(min) = 8,3 mm |

| 16 mm | Lg(min) = 13,2 mm | Lg(min) = 12,2 mm | Lg(min) = 12,2 mm | Lg(min) = 11,8 mm | Lg(min) = 11,7 mm | Lg(min) = 11,3 mm |

| 19 mm | Lg(min) = 16,2 mm | Lg(min) = 15,8 mm | Lg(min) = 15,2 mm | Lg(min) = 14,8 mm | Lg(min) = 14,7 mm | Lg(min) = 14,3 mm |

| 25 mm | Lg(min) = 22,2 mm | Lg(min) = 21,8 mm | Lg(min) = 21,2 mm | Lg(min) = 20,8 mm | Lg(min) = 20,7 mm | Lg(min) = 20,3 mm |

We recommend the use of screws with washers. x max. = distance from the last complete pitch of screw thread to the bearing area (head base) / U = length of the incomplete thread Lg = distance from the base of head or washer to the last complete pitch of screw thread | ||||||

THREAD PARAMETERS

Self tapping screw thread in accordance with ISO 1478.

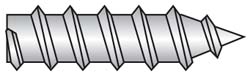

POINTED FORM (B) C

The self tapping screw thread with point - form C - is supplied predominantly for the joining of metal sheets. The thread pitch is narrower than is the case with the thread type with the point form A.

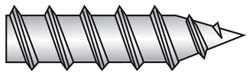

POINT FORM A

The self tapping screw thread pointed – form A – is also supplied for the joining of metal sheets. However, the thread pitch is larger than is the case with the thread type with the point form (B) C. (Application: for example in order to draw in the second sheet when Zeppelin heads are employed).

TAPITS

The Tapits screw thread with a “needle point“ is supplied for the joining of thin metal sheets, which do not need to be predrilled. The “needle point“ with the steep double thread pitch is easy to work with.

DIRVE FORMS

The mode of drive of a screw meets a diversity of purposes. On one hand these can make sense for visual reasons, on the other hand, it is usually the mechanical properties that are the reasons for the selection of the appropriate mode of drive.

HEXAGON HEAD WITH SLOT

The six outer areas allow the practising of optimum power transmission with the socket wrench (extremely high transmittable torque). The additional slot allows reworking or dismounting.

PAN HEAD CROSS RECESSED (H-PHILLIPS)

The inner drive form (conical drive = self clamping - screw/bit) allows a good transmission of the torque, however, it is lower compared to the hexagon head. The cross recessed drive could be damaged/destroyed in the case of overwinding.

PAN HEAD WITH SQUARE DRIVE (WITH AND WITHOUT SLOT)

The square drive form (conical dThe square drive form (conical drive = self clamping - screw/bit ) a torque, however, it ist lower compared to the hexagon head. The additional slot allows reworking and dismounting. The square drive could be damaged/destroyed in the case of overwinding.

TECHNICAL DATA

TESTS IN ACCORDANCE WITH YOUR INDIVIDUAL APPLICATION AND BASED ON A LOT NUMBER CAN BE OFFERED AS FOLLOWS

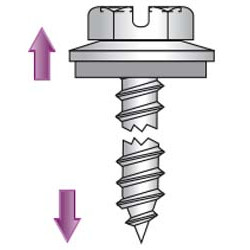

TENSILE STRENGTH

The tensile strength indicates the resistance with which the screw opposes axial tension.

Thedefinitions of the tensile strength are the failure parameters of the screw.

SHEARING STRENGTH

The shearing strength defines the resistance with which the screw opposes tangential shearing forces.

The definitions of the shearing strength are the failure parameters of the screw.

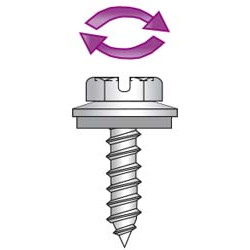

TORSIONAL STRENGTH

The resistance to distortion defines the stability of the screw against distortion.

The definitions of the torsional strength are the failure parameters of the screw.

EXTRACTION RESISTANCE

The extraction resistance defines the stability of the screw during extraction from the component.

The definitions of the extraction resistance are the failure parameters of the screw.

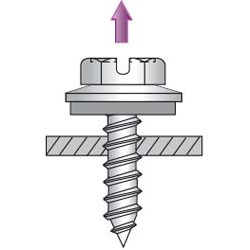

PULL-THROUGH STRENGTH

The pull-through strength defines the procedure during which the metal of the component is torn out via screw head.

SURFACE COATINGS

GOEBEL SILVER GL SLIDE COATING

The Goebel silver GL slide coating provides optimum sealing with multifunctional properties, which guarantee excellent corrosion protection and simultaneously reduce the screw-in resistance. It is available in different colours: e.g. silver, black, green and red.

Properties: superior adhesive strength, high hardness with good flexibility, high abrasion resistance, good resistance to weathering, (but not chalk resistant), high electrical insulating property (good protection against contact corrosion), superior resistance to chemicals, superior resistance proven in salt spray test, excellent resistance to sulphur dioxide proven in Kesternich test, excellent resistance to mineral oil, fuels, lubricants and grease, brake fluids, coolants, etc.

*Advise: The GOEBEL-silver-slide-coating provides no UV light resistance, though having a good chemical resistance. When using the GOEBEL-silver-slide-coating in production areas with a strong aggressive atmosphere this can react to certain alkalis and acids, e.g. in vinegar production. This also applies to various cleaning agents and disinfectans. Therefore, the GOEBEL-silver-slide-coating should be tested in the environment before starting construction.

ZINC PLATING (CHROME VI FREE)

By zinc plating the steel is coated with a thin layer of zinc (standard for mounting components 4 – 6 μ) in order to protect it from corrosion. When it has been freshly applied, the zinc layer has a bright sheen and then develops a metallic crystalline appearance for some time. In the course of time it becomes dark grey as a consequence of the corrosion of the zinc, which forms a weatherproof protective layer of zinc oxides and zinc carbonate when exposed to air. If the exposure to air and hence the inlet of carbon dioxide is restricted, undesirable white corrosion will occur.

In contrast to more noble metals such as steel, zinc plays the part of a sacrificial anode, protecting the underlying steel from corrosion until itself is completely corroded. As a consequence of these two material properties, a zinc lay-er of corresponding thickness can provide an economical corrosion protection for decades without any maintenance expenditure (As the thickness of the zinc layer is limited in the mounting components, we recommend supplementary corrosion protection for these parts Goebel silver GL slide coating).

POWDER COATING

Powder coating or powder lacquering is a coating process during which an electrically conductive material is coated with powder lacquer. The powder coating predominantly serves the visual matching of the screw heads / washers to the component. Furthermore, the corrosion resistance of the coated part will be enhanced.

VARNISHING

Varnishing is a coating process during which the fastener is coated with liquid varnish (painting). The varnishing predominantly serves the visual matching of the screw heads / washers to the component. Furthermore, the corrosion resistance of the coated part will be enhanced.

WASHERS

EPDM WASHERS (EPDM = ETHYLENE-PROPYLENE-DIEN-MONOMER RUBBER) ARE UNDETACHABLY PITCHED BY MACHINES ON THE SCREWS

These approved connecting elements ensure secure and sealed fastening and sustainably improve the dynamic strength and stability of a connection.

Standard diameters: 12, 14, 16, 19 mm

On request washers can be supplied in supplementary diameters: 9 - 70 mm

Material: stainless steel (R), steel zinc plated (S), aluminium (A), further materials available.

EPDM washers possess a high resistance to wear and tear (UV and ozone resistance as well as a high thermal resistance), weathering (resistance to weather and humidity), and heat (temperature resistance from –30° to +130° degrees Celsius). Moreover, they exhibit a high resistance to hot water, steam, cleaning agents and detergents. Resistant to diluted acids and brake fluids on a non-mineral oil basis. Not resistant to petroleum products!

POLYAMIDE WASHERS (PA 6.6) ARE UNDETACHABLY PITCHED BY MACHINES ON THE SCREW

Polyamide possesses the following properties (PA) 6.6: Physical properties: halogen free, flame resistant and self extinguishing.

Colour: natural

Dimensions: 2 mm thickness x 10 mm outer diameter

Customer and laboratory tests have shown that only PA washers with a thickness of 2 mm x 10 mm outer diameter perform a reliable sealing function.

Mounting temperature: -10° to + 85° C

Service temperature: -40° to + 85° C

Resistance to UV radiation: good (approx. 12 years / Central Europe)

Chemical properties:

Excellent resistance to

- Alkalis

- Oils

- Lubricants, grease

- Oil products

- Solvents

Limited resistance to

- all kinds of acids

No resistance to

- phenol

Both washer types perform a sealing function. EPDM washers possess a greater bearing area/ diameter. The PA washer is directly exposed to weathering (for example UV radiation). The steel and stainless steel washers, which are mounted above the sealing EPDM washer, protect the EPDM and prevent direct exposure to weathering. They seal better than polyamide washers because the metal is more rigid and the EPDM is more flexible.

Note: Polyamide washers could burst in the case of high contact pressure. A protruding burr from the sheet could cause damage / cracks in the polyamide washer. Hence the sealing function is no longer guaranteed.