Multi-Grip Blind Rivets

MULTIGRIP BLIND RIVETS MULTI

Applications

- air-conditioning

- construction works

- tank and housing construction

- construction of vehicles

- furniture industry and many others

Characteristics

- suitable size of drilled hole ensure dust and splashproof connections

- high clamping capacity

- large closing head for big and noncircular holes or repair jobs

- remainder of mandrel is retained inside rivet

Head shape

Domed head

Large head

Countersunk head

MATERIALS

Al = Alu

ST= Steel zinc plated

A2 = Stainless steel A2

A4 = Stainless steel A4

Available in the following qualities

COLOURED BLIND RIVETS RAINBOW MULTI

Applications

- window/frame construction

- canopy tops

- cladding panels (metal/plastic)

- car body production and many others

Characteristics

- colour match of riveted components

- almost every type of rivet listed here could be painted

Head shape

Domed head

MATERIALS

Al = Alu

ST= Steel zinc plated

Available in the following qualities

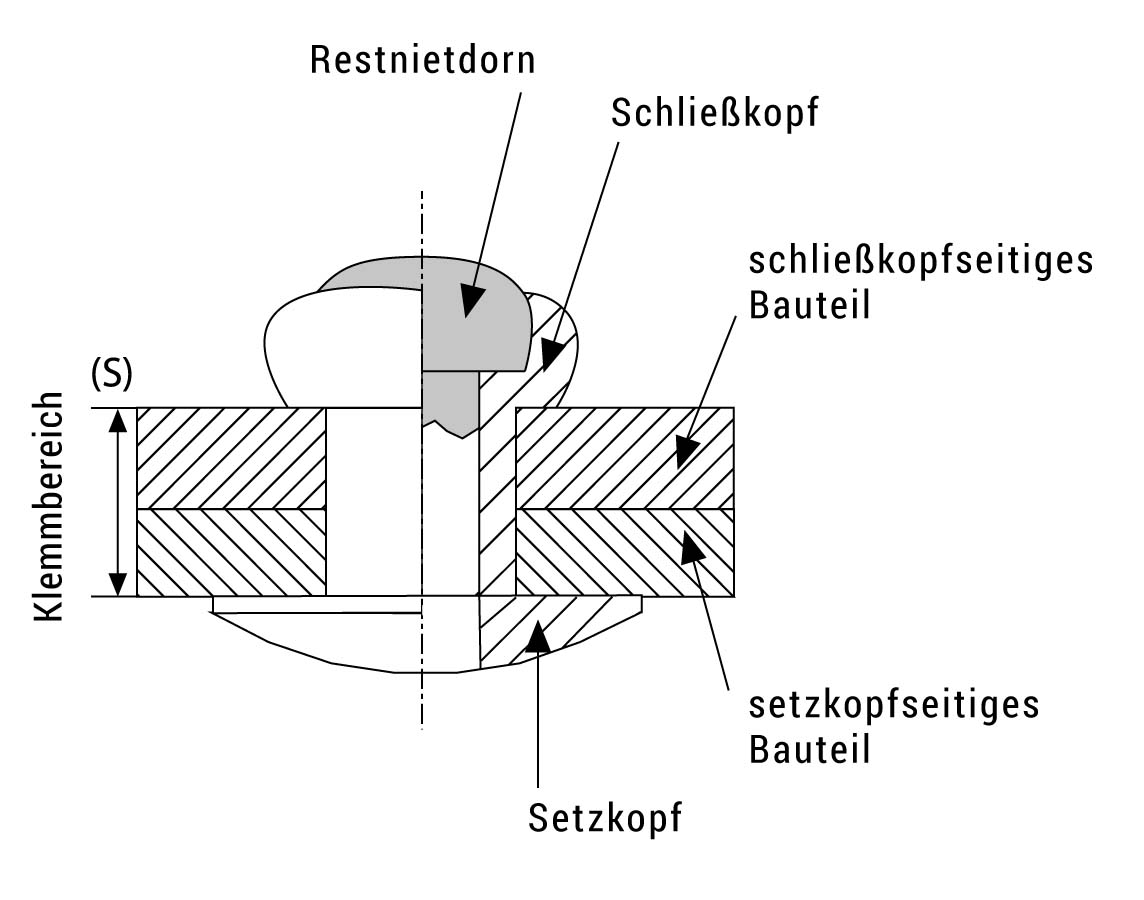

TECHNICAL EXPLANATIONS

|  |  |  |

| Grip range of the rivet. |

| The named shearing strength (N = Newton) in this catalogue are minimum values, determined according to test method ISO 14589 (2000), which the rivet meets on average in a defined test series. |

| The named tensile strength (N = Newton) in this catalogue are minimum values, determined according to test method ISO 14589 (2000), which the rivet meets on average in a defined test series. |

| (1 kp ≈ 10 N ) | |

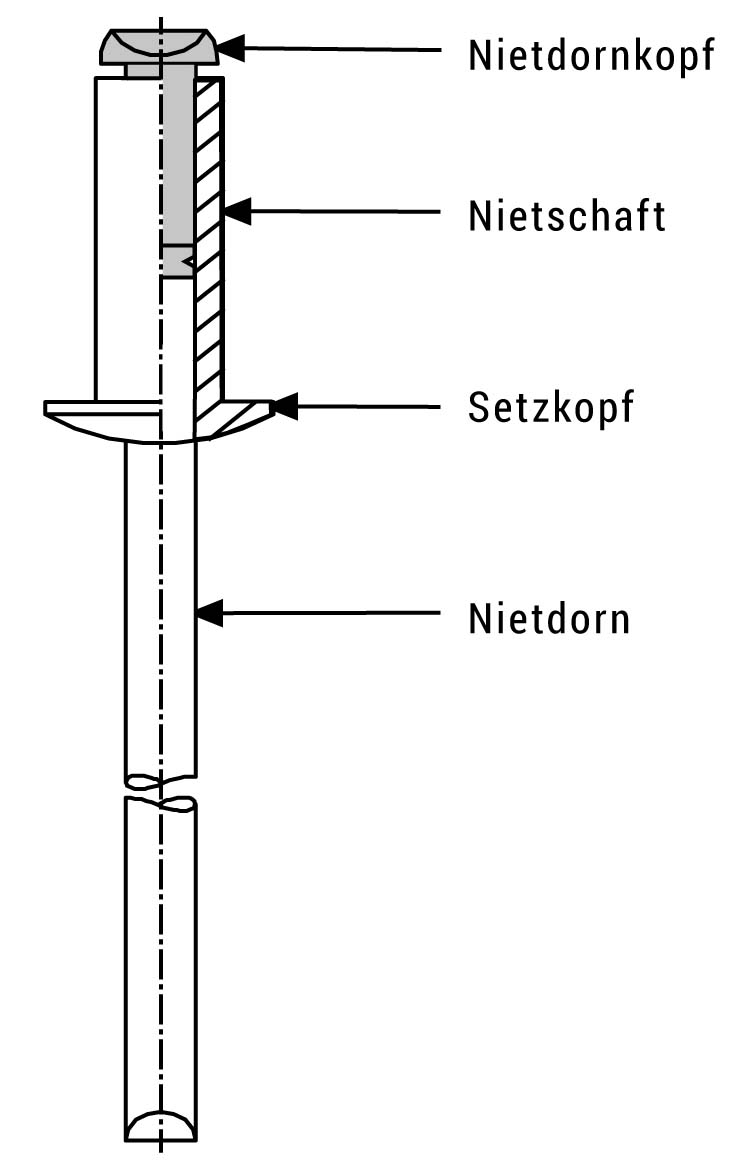

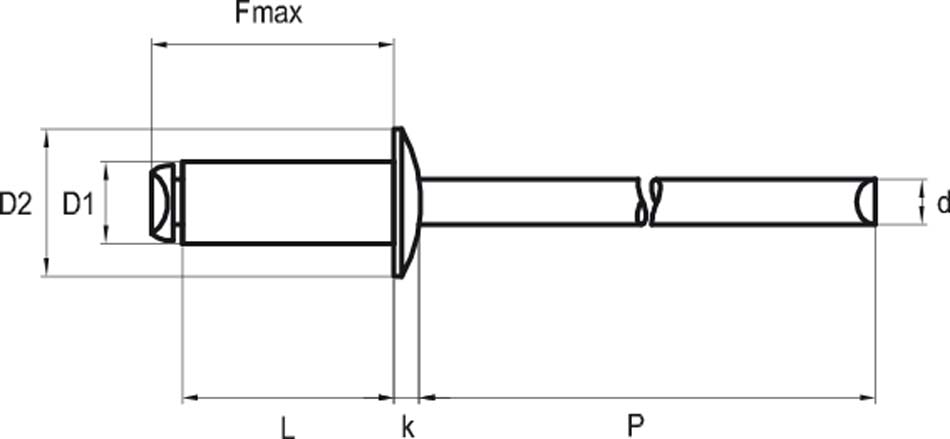

TECHNICS

Length (L)

Nominal Diameter (D1)

Head Diameter (D2)

Head Height (k)

Mandrel Diameter (d)

Mandrel Length (P)

If you are searching for a quality, a material combination or a measurement which is not listed in the catalogue, please don’t hesitate to contact us.

Alternatively we got the possiblity to develop a blind rivet type especially for your application. For Example:

- softer breaking point 1

- displaced breaking point 2

- grooved mandrel 3

- longer mandrel 4

etc.

TESTS ACCORDING ISO 14589

This inspection ISO 14589 includes the following points.n

Principle of shear and tensile tests

The tests consist of straining a blind rivet which is set in a test fixture by a shear load or tensile load to failure.

Principle of mandrel push out restistance test (prior to setting)

The test consists of loading the mandrel axially from the head side of a blind rivet untill it is pushed out.

Principle of mandrel push out restistance test (prior to setting)

The test consists of straining the mandrel removed from the rivet body in a test fixture by a tensile load to fracture.

Principle of head retention capability test

The test consists of loading the mandrel axially, from the head side of a set blind rivet up to the head retention load. All details in Newton, 1kp = 9,80665 N (10N)

For every delivered batch GOEBEL is able to handout the inspection report. With this procedure it is guaranteed that only tested items will be delivered for a customers safe treatment.

Shearing test

Tensile test

Mandrel push out test

Mandrel breaking test

Mandrel retaining test